We appreciate your interest and will get back to you as soon as possible to prepare a quote. In the meantime, feel free to discover more products on our website.

Product information

Description

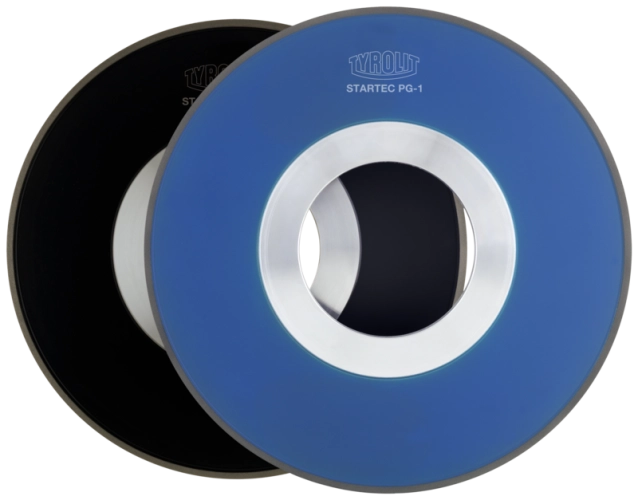

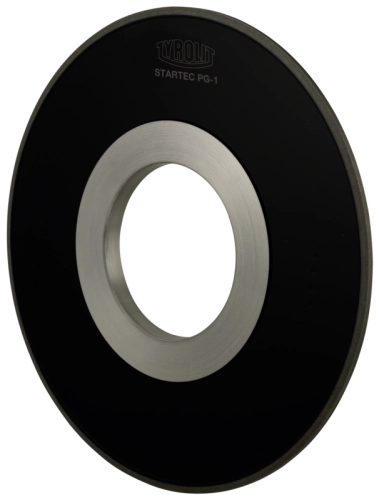

With the STARTEC PG-1 product line, for the first time TYROLIT is offering innovative roughing and finishing wheels for the peel grinding of tungsten carbide tool blanks in particular. A high-strength metal bond is used for the roughing wheel. This enables especially cost-effective and reliable process control. Long-life vitrified or metal bonds are used for the finishing wheel. This enables even large stock removal fluctuations to be compensated after roughing, and maximum surface quality to be achieved.

Features

-

Maximum stock removal rate:

The use of new specifications enables a feed increase of up to 25% when rough grinding.

-

Reduced grinding noise:

New raw materials, a tailored wheel design and the optimum process setting selected by TYROLIT application engineers significantly reduce grinding noise.

-

Reduced wheel wear:

The combination of process-optimised diamond quality and the new bond system reduces wheel wear by up to 10% when rough grinding.

-

Extremely rapid availability:

Selected STARTEC PG-1 grinding and dressing tools are kept in stock and can therefore be supplied extremely quickly.

Abrasive Grain

- Diamond (D)

Bond Classification

Vitrified

Recommendations

Explore related products

CNC tool grinding with metal-bonded CBN for wet grinding

For high-alloyed steels and HSSTool grinding

CNC tool grinding with metal-bonded CBN for wet grinding

For high-alloyed steels and HSSTool grinding