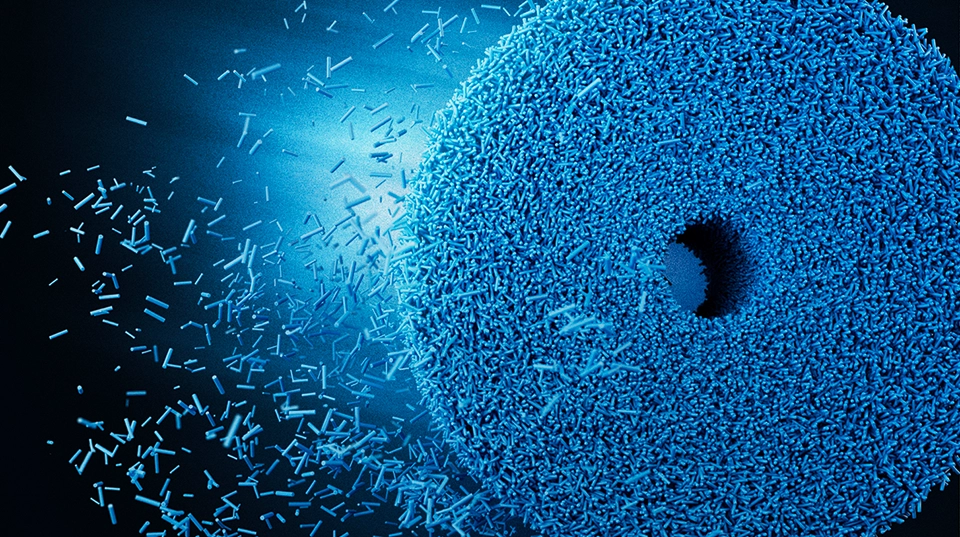

Get there faster - the ceramic abrasives of the CERABOND X product family are among the highest quality of their kind worldwide.

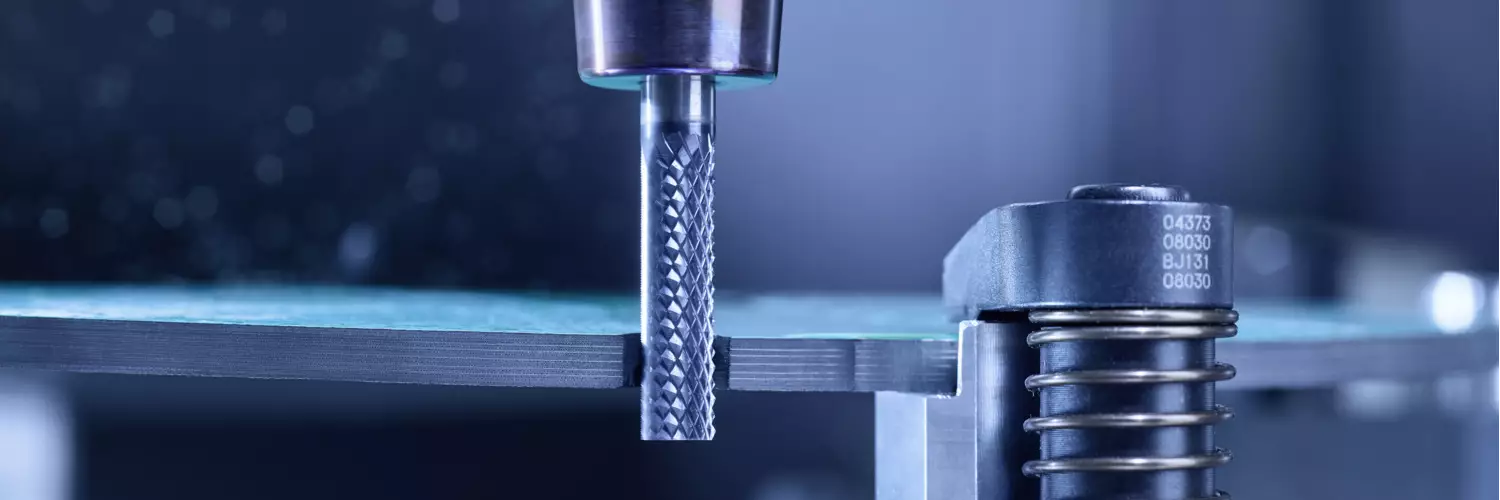

However, the best grain in the world is of only limited use if it is not supported by an equally first-class bond. With the CERABOND system, Tyrolit has succeeded in designing an optimum combination of a ceramic grain of the highest quality and an innovative bond structure.

CERABOND X offers a wide range of specifications, from highly efficient cutting and roughing discs, to fiber discs with cooling layer, to trimmable flap discs and sustainable natural fiber discs. In addition, our assortment includes abrasive belts that significantly reduce the operator's workload and thus guarantee greater safety. This extensive range of products enables a wide variety of work processes to be accelerated and our customers benefit from unique quality for processing steel and stainless steel.