We appreciate your interest and will get back to you as soon as possible to prepare a quote. In the meantime, feel free to discover more products on our website.

Product information

Description

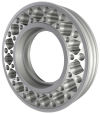

stock removal rate at the core is not random, but is calculated using a computational FEM analysis (Finite Element Method). This means that deformations and potential performance losses can be excluded. Through use of the lightweight POLARIS LW version, the maintenance intervals at the grinding machines can be reduced and handling significantly simplified for personnel in production.

Features

-

Weight optimisation:

Through targeted material reduction at the core, weight reductions of up to 50 percent can be achieved. POLARIS LW tools determine less wear on spindles and bearings than comparable reference tools. Moreover, significant advantages arise during transport and fitting of the tools. A patent has been applied for with regard to this innovation.

-

Maximum tool life:

POLARIS LW tools provide the customary top performance of the proven POLARIS product lines. Thanks to the weight reduction, tool life increases are often possible as a side-effect, e.g. due to a reduction in vibration.

-

Replating-compatible:

POLARIS LW tools can be replated problem-free. The slightly higher purchase price is quickly compensated through the replating of existing lightweight cores.

-

Computational FEM simulation:

Each lightweight version is optimally designed for the requirements at hand with the aid of a computational FEM simulation. This allows maximum weight reductions to be achieved without sacrificing on performance.

Abrasive Grain

- Diamond (D)

Bond Classification

Galvanic

Recommendations

Explore related products

Ceramic external cylindrical grinding wheels

for tungsten carbide and grey cast ironExternal cylindrical grinding

CSS ROLL STAR 2.0 HYBRID

Grinding wheels for roll grindingExternal cylindrical grinding

CSS ULTRA

High performance grinding tools for external cylindrical grinding and thread grindingExternal cylindrical grinding

CSS WIRE ROLL

The solution for grinding tungsten carbide wire milling rollsExternal cylindrical grinding