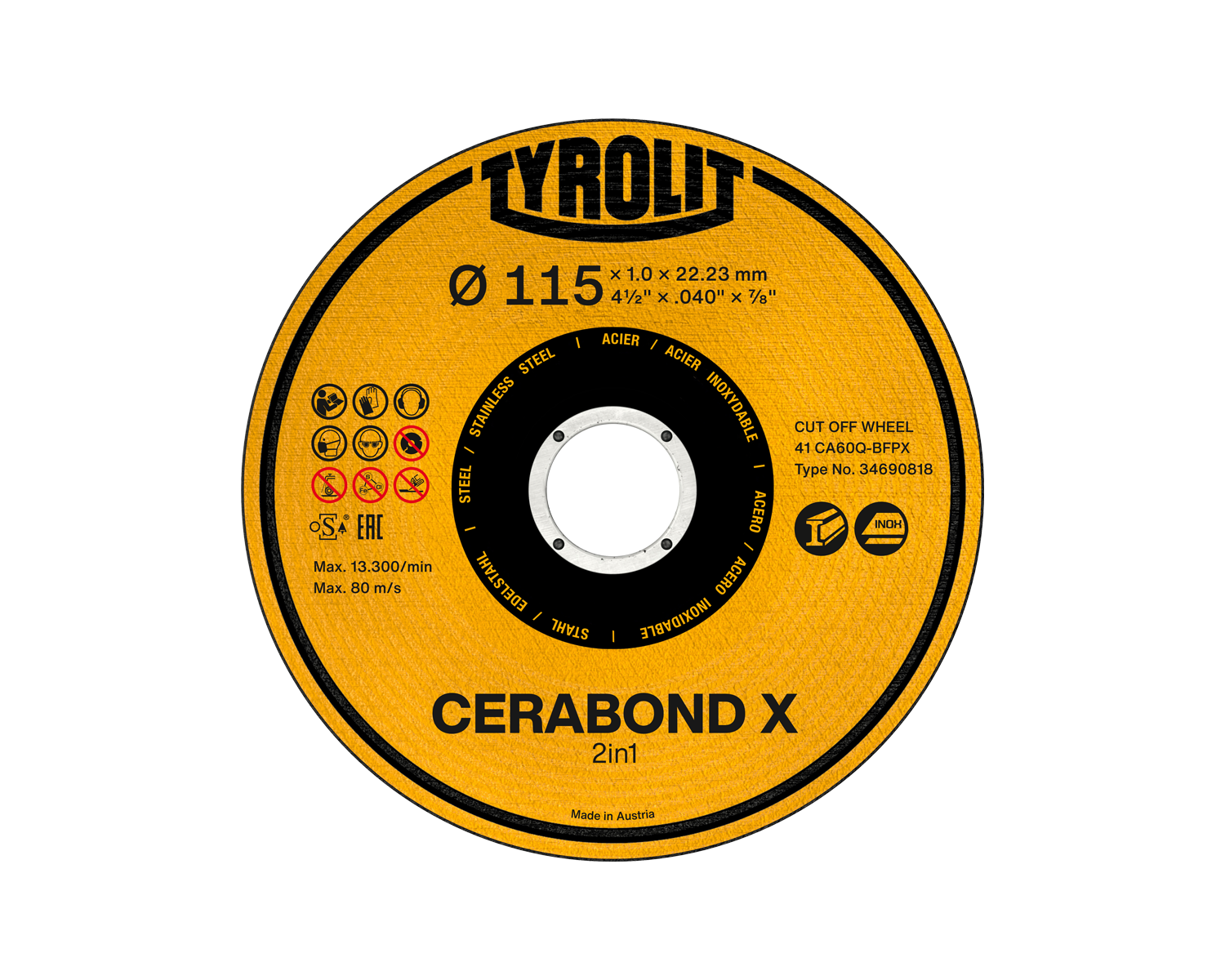

CERABOND X is characterized by a specially developed ceramic abrasive grain that is manufactured in Tyrol. In contrast to conventional abrasives, where the grains detach completely and the wheel quickly becomes dull, the CERABOND X grain breaks in a controlled manner. As a result, new, sharp edges are constantly being created, ensuring consistently high aggressiveness and cutting ability over the entire service life of the disc.

More information about CERABOND X:

» CERABOND X technology - revolution in the grinding and cutting process | Tyrolit